How to Install 6mm Armoured Cable: A Comprehensive Guide

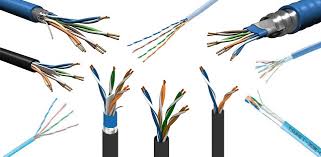

6mm armoured cableare renowned for their robustness and reliability, making them an ideal choice for demanding electrical installations. These cables that are protected by a layer of aluminum armor or steel wire, are designed to withstand mechanical stresses and environmental challenges. But regular inspection and maintenance are crucial to ensure their continued security and effectiveness. This guide will help you in keeping and reviewing six millimetre armoured cables.

Routine Visual Inspections: Frequently inspect the visible sections of the armored cable for evidence of wear or physical damages. Look for any fraying, cracks, or corrosion on the cable’s external sheath or armor. Examine for signs of mechanical stress or impacts which could affect the cable’s strength. A quick detection of issues can prevent potential electrical dangers.

Verify connections and terminations Check the cable connections and terminations for any loose or corroded connections. Check that all connectors are securely attached as well as that your cable has been correctly terminated. Poor connections can lead to increased resistance, overheating, and the possibility of failure.

Review the cable Route: Evaluate the cable’s route to installation for any potential risks. Check that the cable is not exposed to excessive strain, sharp bends, or scratching. Cables must be supported and protected along their length to protect them from damage. If the cable runs through areas that are susceptible to physical damage, consider additional measures of protection, like cables trays or conduits.

Be aware of environmental damage Protected cables are designed to withstand extreme environmental conditions, however constant exposed to high temperatures, moisture or other chemicals may affect their performance. Check for any indications of wear and tear including moisture intrusion or chemical damage, which could impact the cable’s insulation as well as its armor.

In conclusion keeping track of and checking 6mm armoured cable involves regular visual inspections, checking for secure connections, examining the cable route as well as examining environmental damage, conducting electrical tests and then promptly taking care of any problems. If you follow these guidelines, you can ensure the continued safety and efficiency of your electrical systems safeguarding personnel and equipment from dangers that could be a threat to them.